The test of time…

Blog 08

May 2023

Good Architecture is like a good sturdy pair of boots.

We often find ourselves making comparisons or analogies describing architecture and the process, to items that are reflective of our ethos towards our craft.

For example, we often reference a good sturdy pair of boots. (I know - where are we going with this? but stick with it!) As architects we tend to adopt a certain uniform - we have all seen the black polo neck stereotype. However for us its all about a sturdy pair of boots.

In todays fast fashion world it is very easy to go online or to a store and purchase a pair of boots at a relatively good price and get on with your day.

However we need to ask ourselves, how long are these going to last? Where have they been made and by whom? and how much were they paid to do so? what chemicals were involved in the process?

Now we are not eco warriors by any means but we do, where we can, like to choose things that are made in the UK and will stand the test of time.

One of our favourites are these beauties:

Old time custom logger style 107F as designed / specified by BM made by the William Lemmon Ltd. New boots that stand the test of time!!

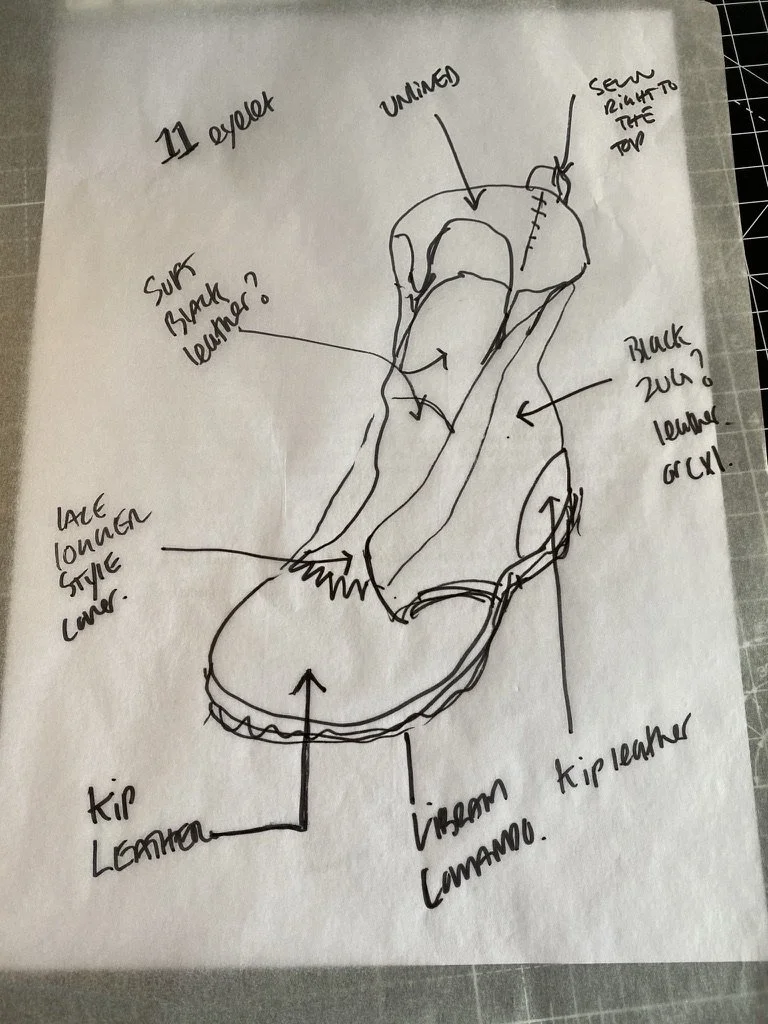

Sketching custom boots

Early boot sketch by BM given to William Lennon Ltd

These are, in our opinion, the best boots around. Made for BM by the team at William Lennon Ltd, Britain's last surviving traditional boot manufacturer. These things can handle any thing you can throw at them , within reason.

Now here comes the analogy between sturdy boots and Architecture:

They are made in Britain as they have been since 1897

They are made to order and took around 12 weeks to arrive.

They are not the cheapest on the market.

They are perhaps a little bit heavier than off the shelf boots.

They take a little longer to put on and take off.

They require occasional cleaning and re-waterproofing with dubbin.

They took around 3 - 4 weeks of progressive wearing to break them in, and for the first few days they are a little stiff and clumpy.

But all of the above - is exactly why we love them!! Once you have gone through the break in process, the long wait to receive them, accepted that you may need to do a little work yourself to keep them in good working condition, you then realise that these are the most comfortable, robust pair of boots around.

The quality leather when broken in works with you and allows your feet to breathe.

With wool socks, they are fantastic in the winter, and with a thin sock they are a great breathable British summer boot.

The parts and pieces can be easily accessed for repair and maintenance.

Much like quality architecture, they are completely custom to you. They are not like fast architecture or off the shelf furniture. These will not be unfit for use or out of fashion in 5 years.

Therefore, paying a little bit more upfront and waiting a little bit longer for them to be created and “bed in” means that they are far more enjoyable and economical over their lifespan.

This, in a round about way, is our attitude to sustainable architecture. Not bolt on technologies or the latest greatest flashy thing but good honest, robust, quality craftsmanship that stands the test of time.

All the best,

BWMA